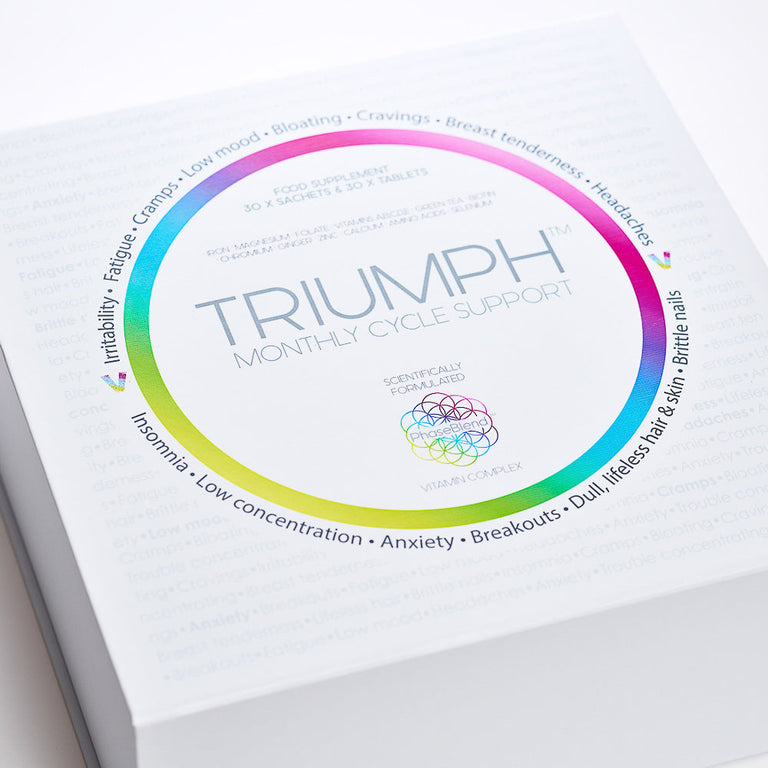

At Foldabox we make it easy to add your own logo or printed design to our stock boxes, to create your own unique branded gift box!

If you'd like to add your own logo to our stock gift boxes, it's easy and the results can look fantastic!

Adding a logo enables you to personalise gift boxes without the large volume commitment and long lead time needed for a fully made to order box.

24 is the minimum number of boxes we can print. 144 or more is the most economic quantity due to fixed origination charges that apply no matter how few or how many boxes you print.

All boxes are packed in 12’s so print quantities are in multiples of 12.

Printing is offered on all boxes available from stock. These boxes are already manufactured so printing options are limited to the outside and inside lid of the box.

We cannot print all over the box, this would require the flat paper to be printed before the box is covered and assembled.

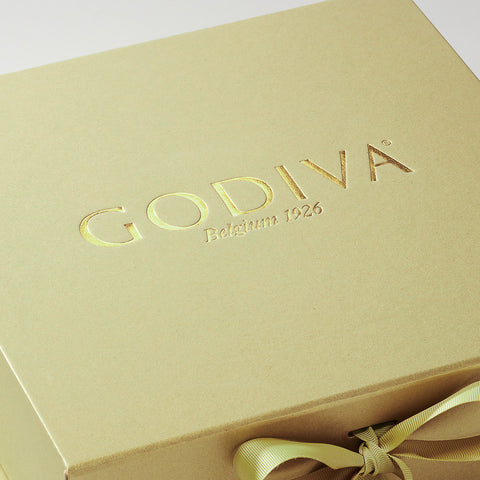

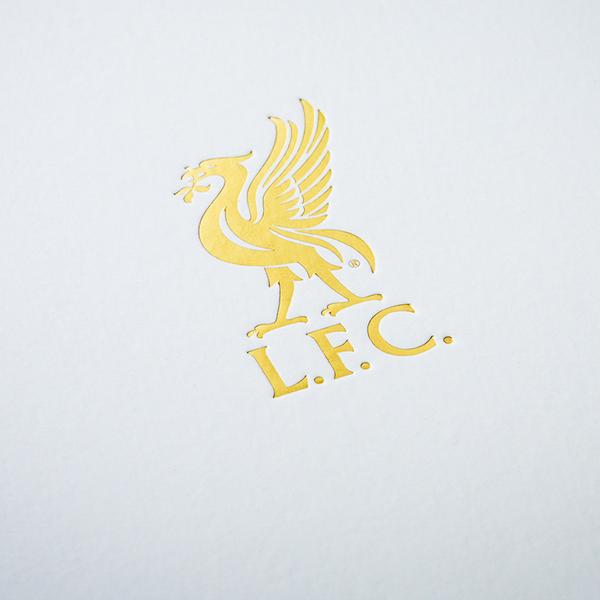

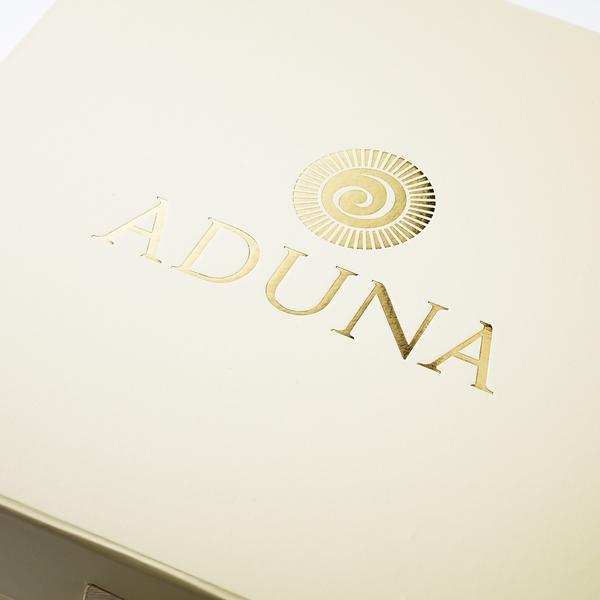

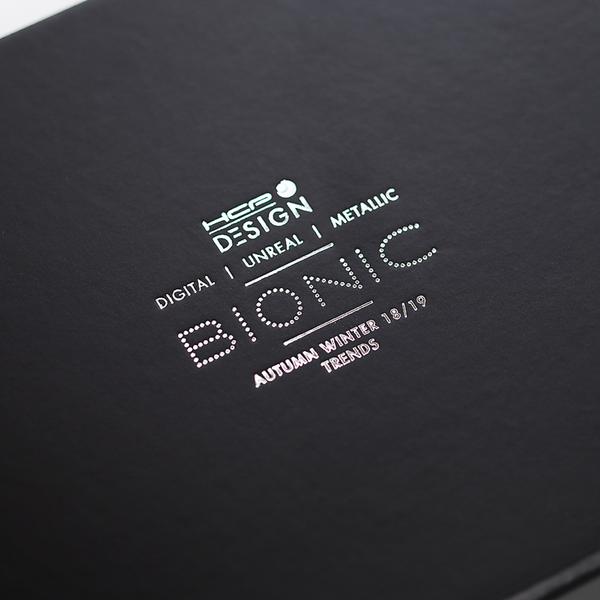

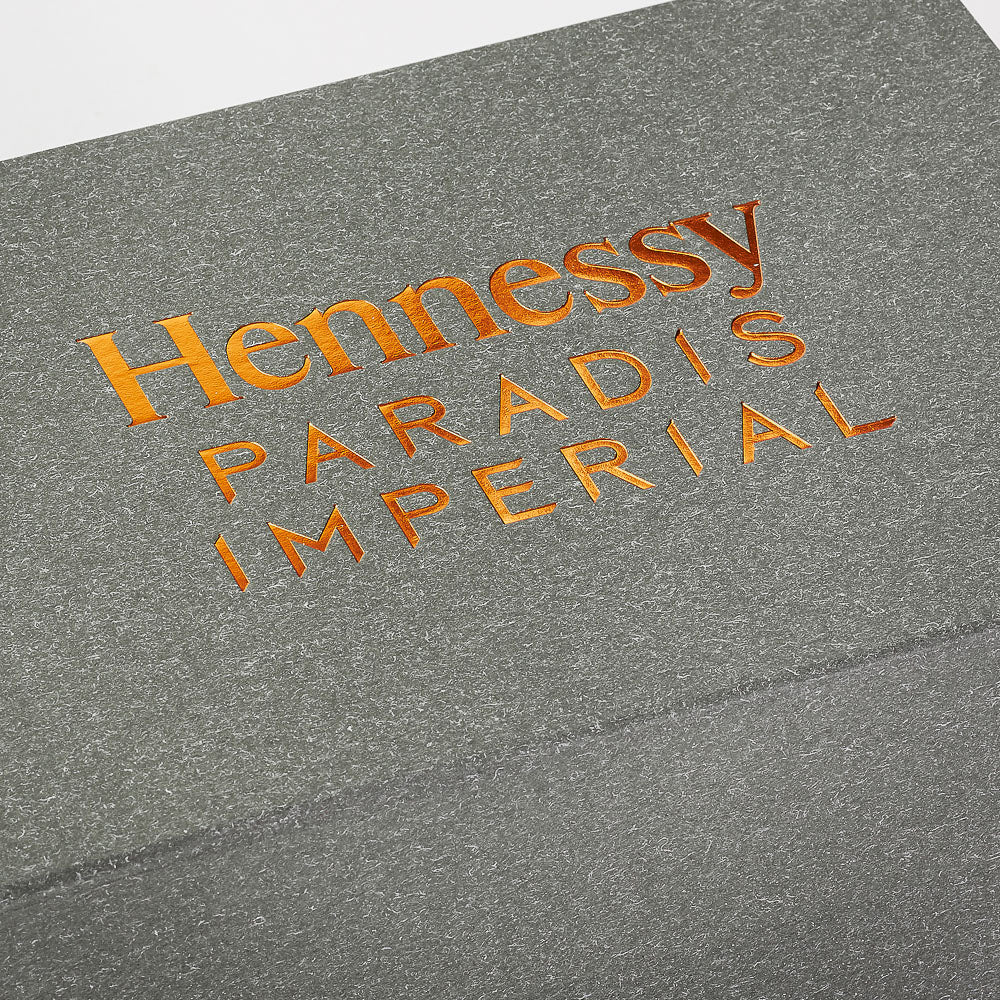

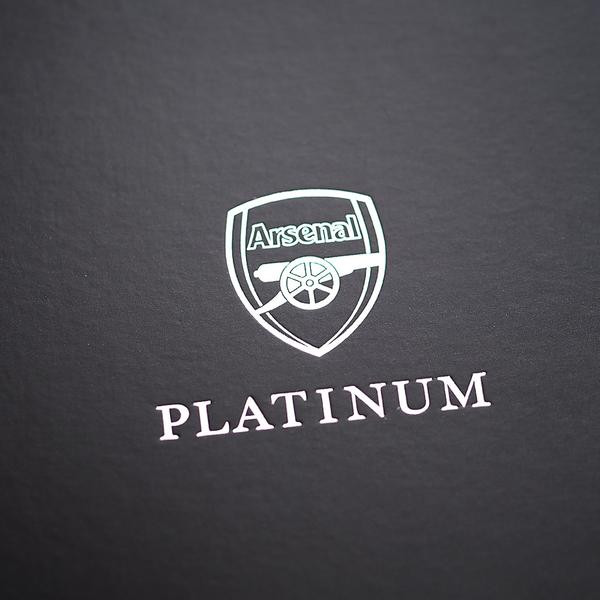

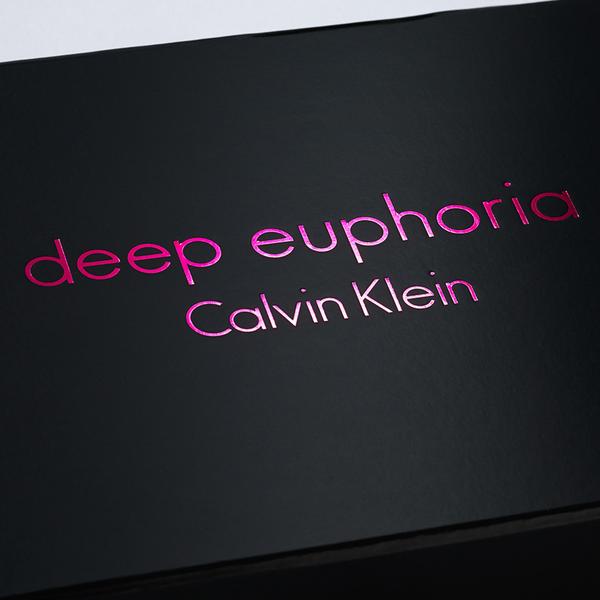

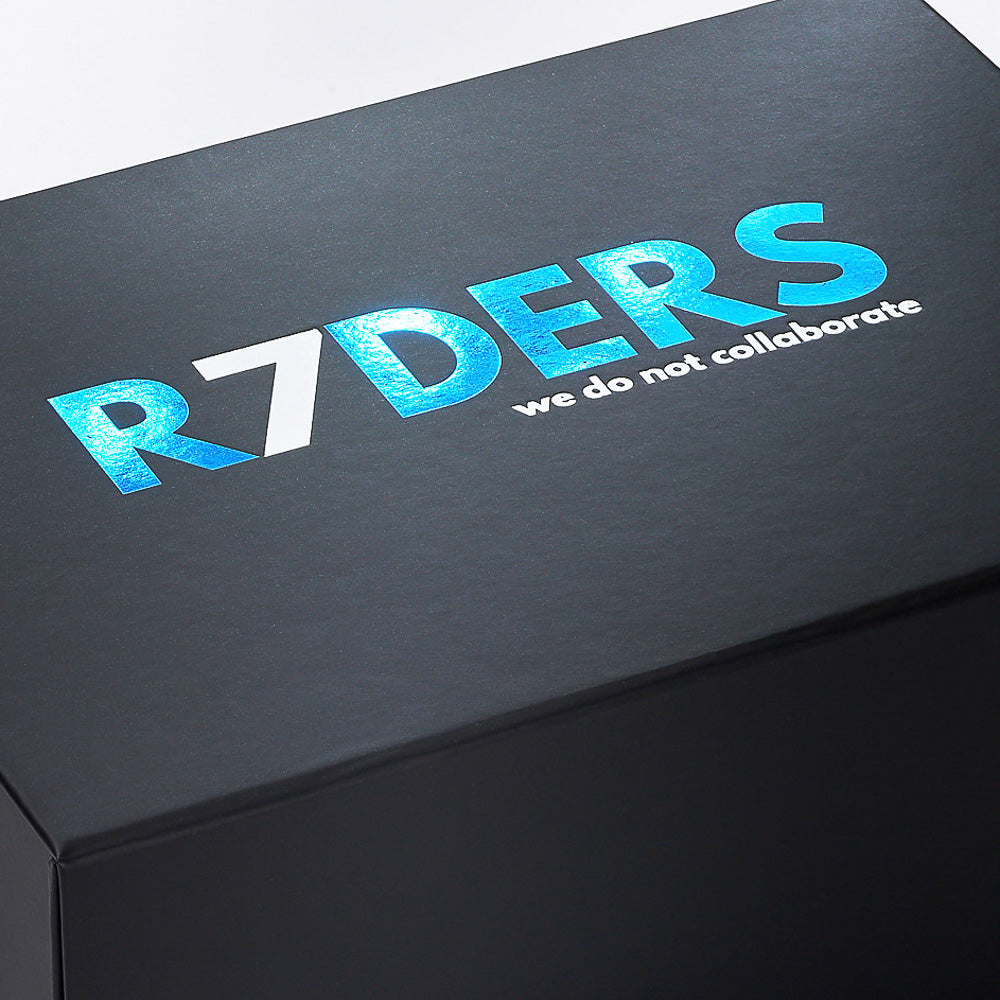

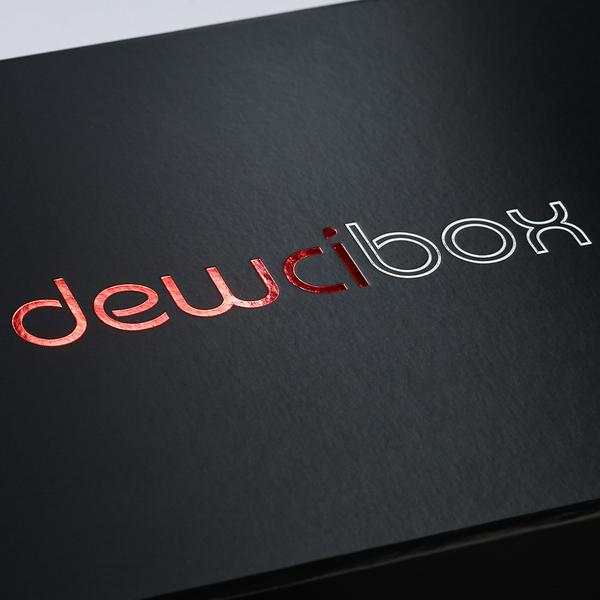

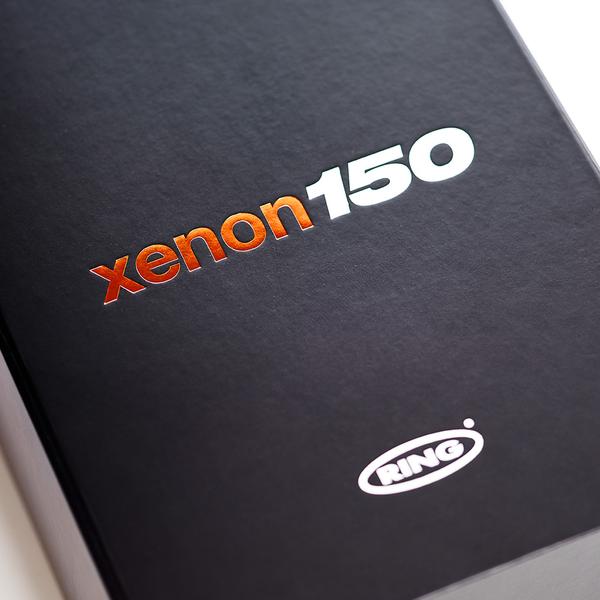

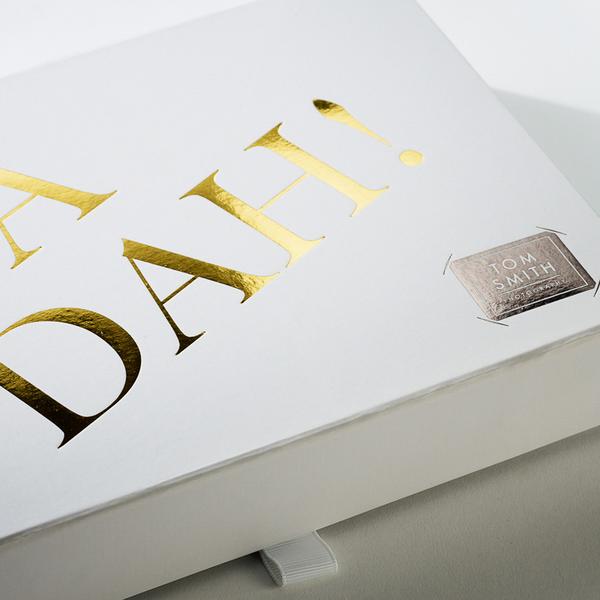

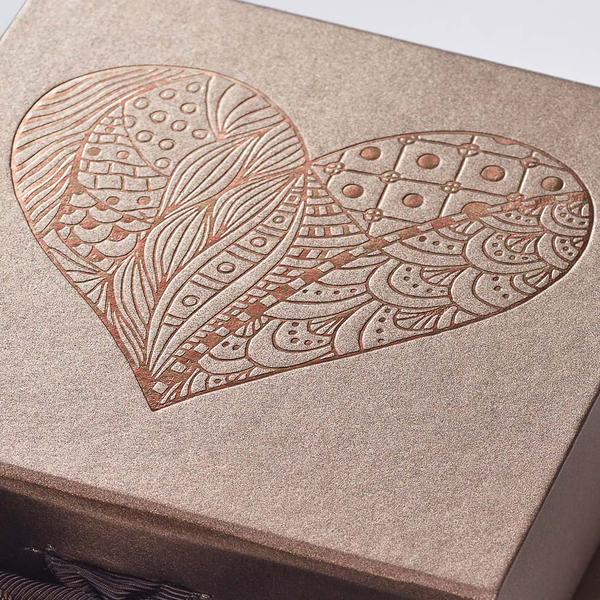

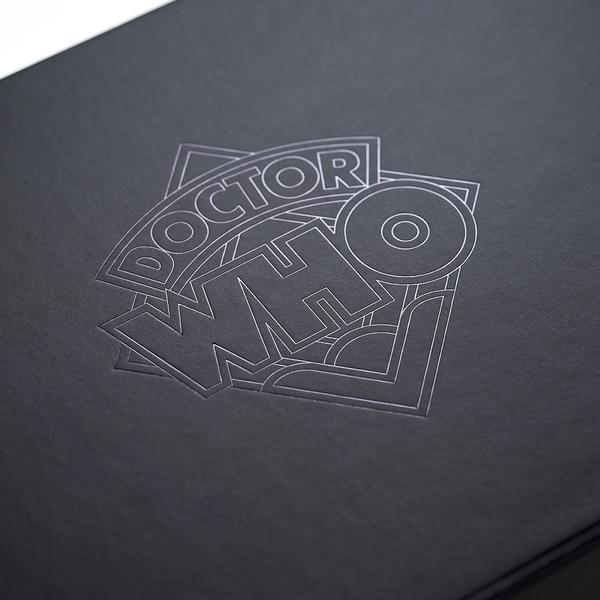

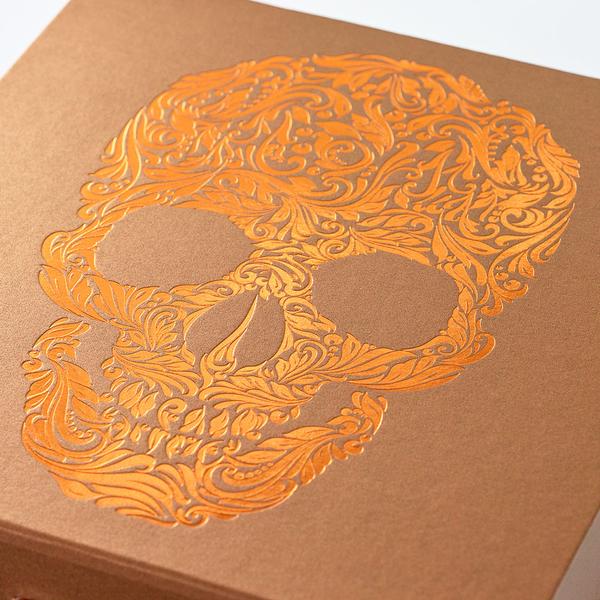

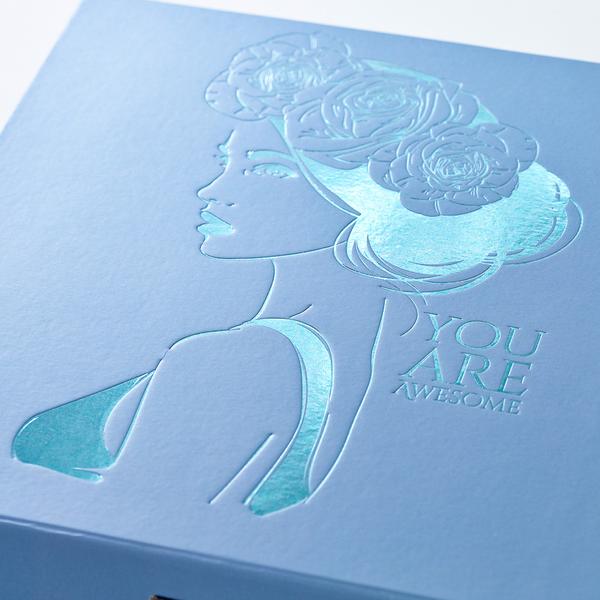

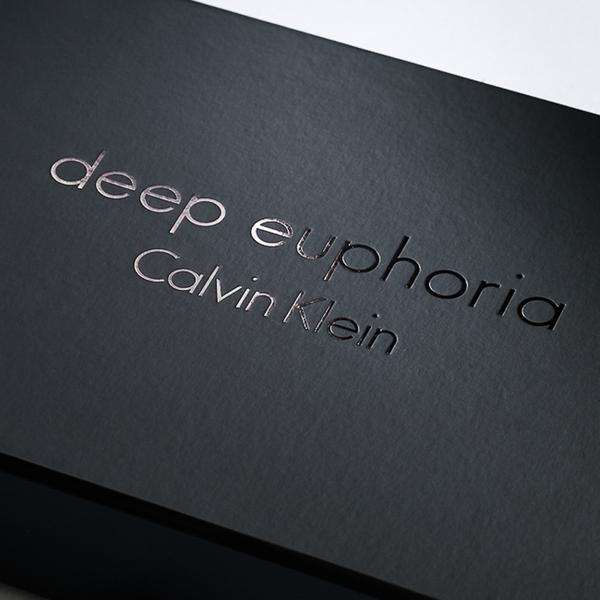

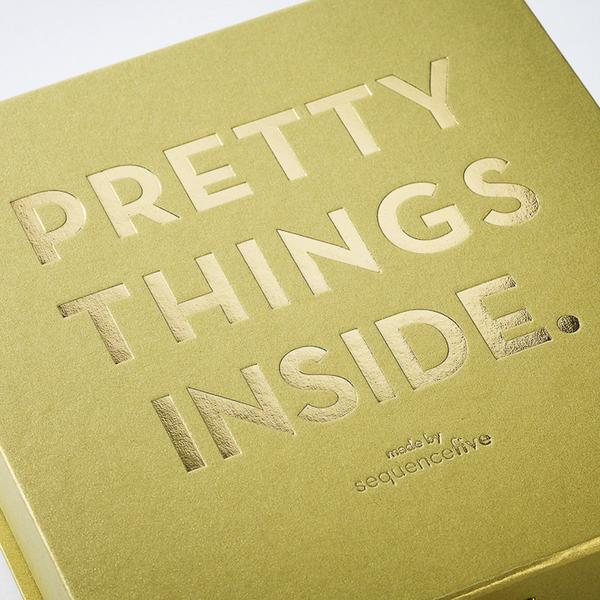

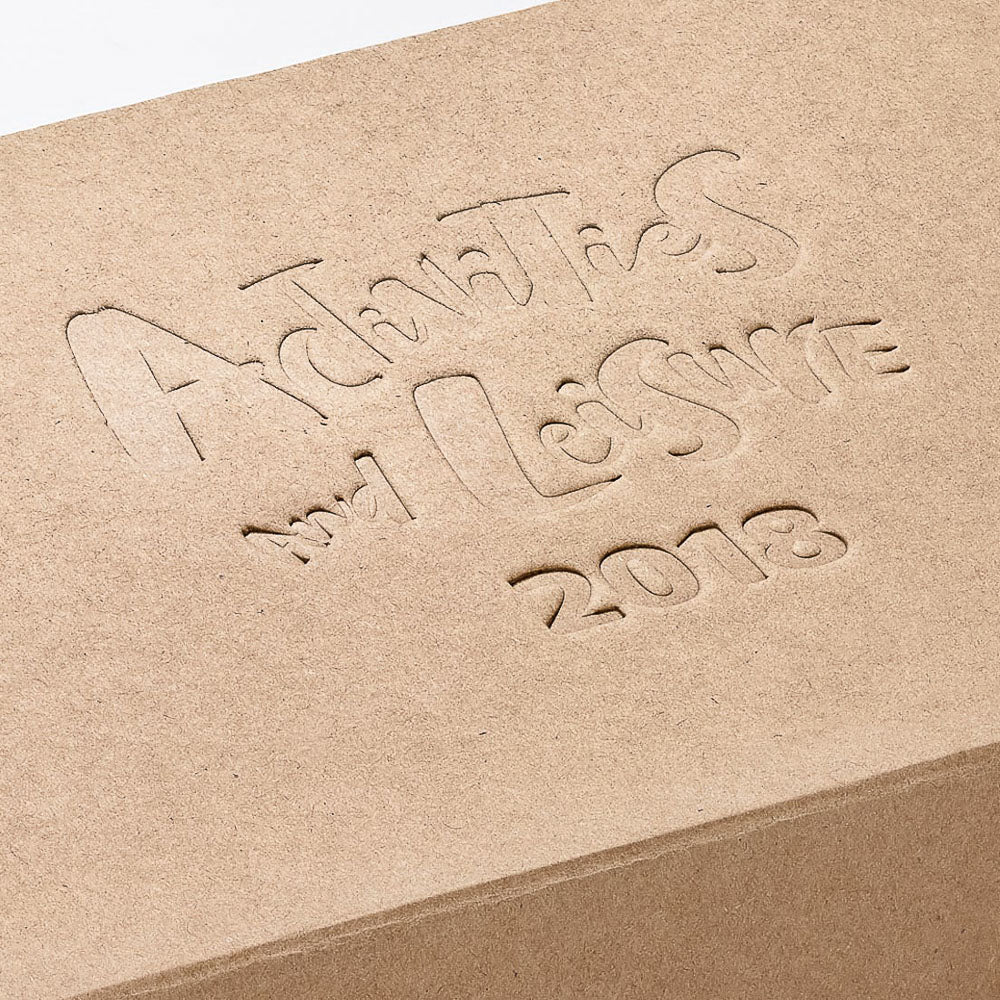

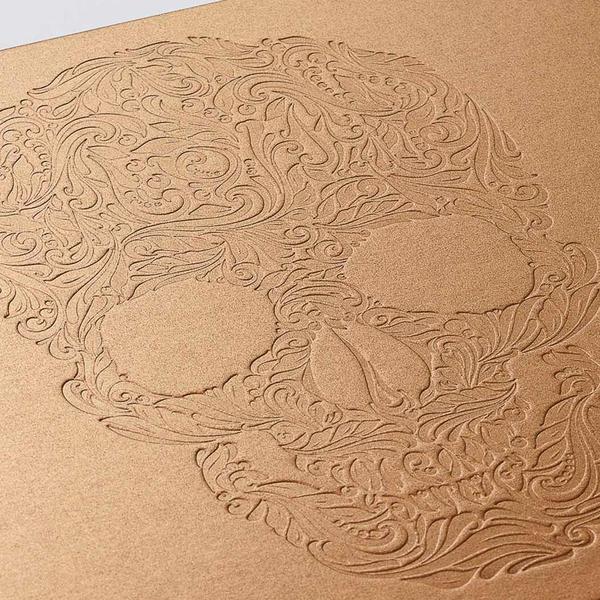

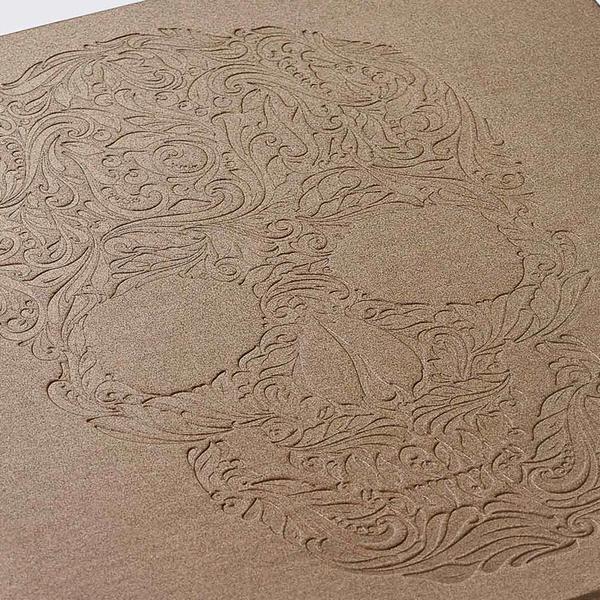

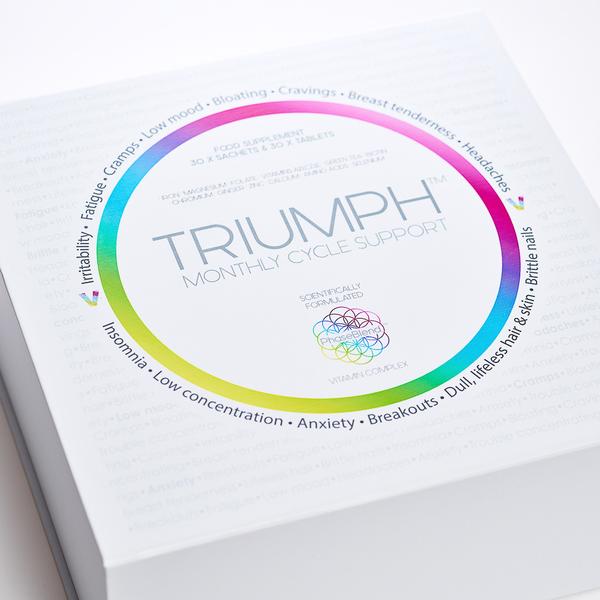

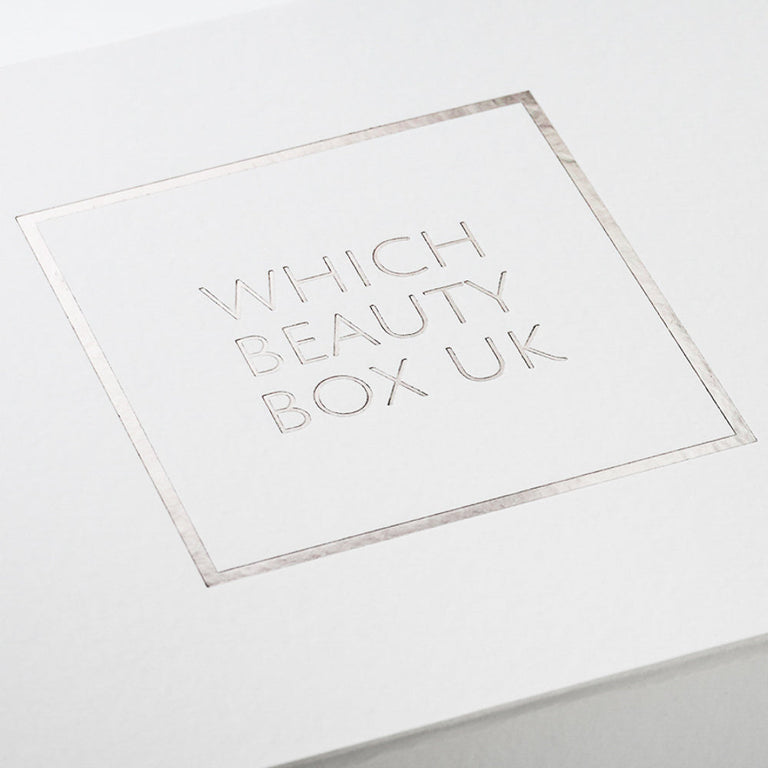

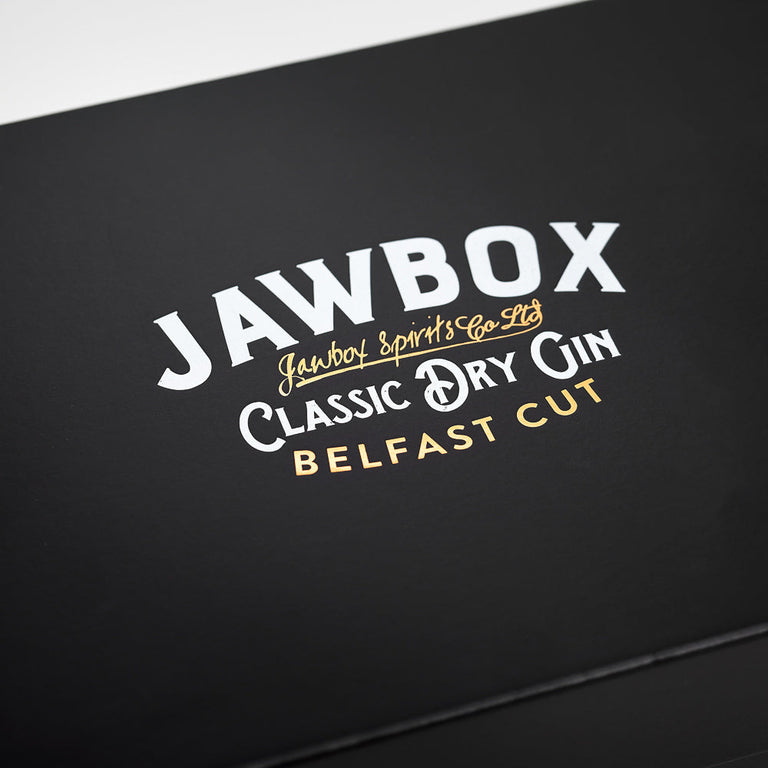

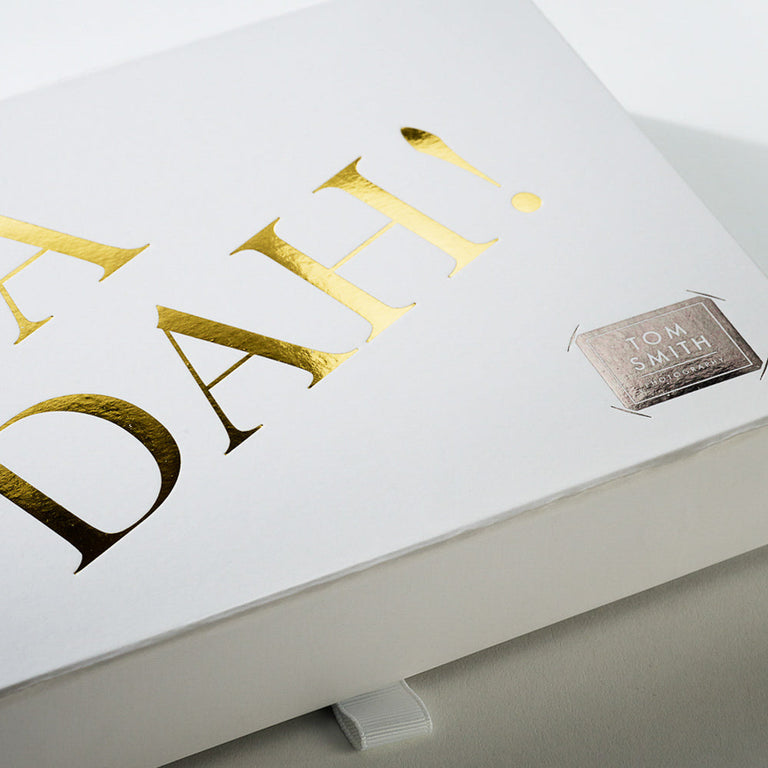

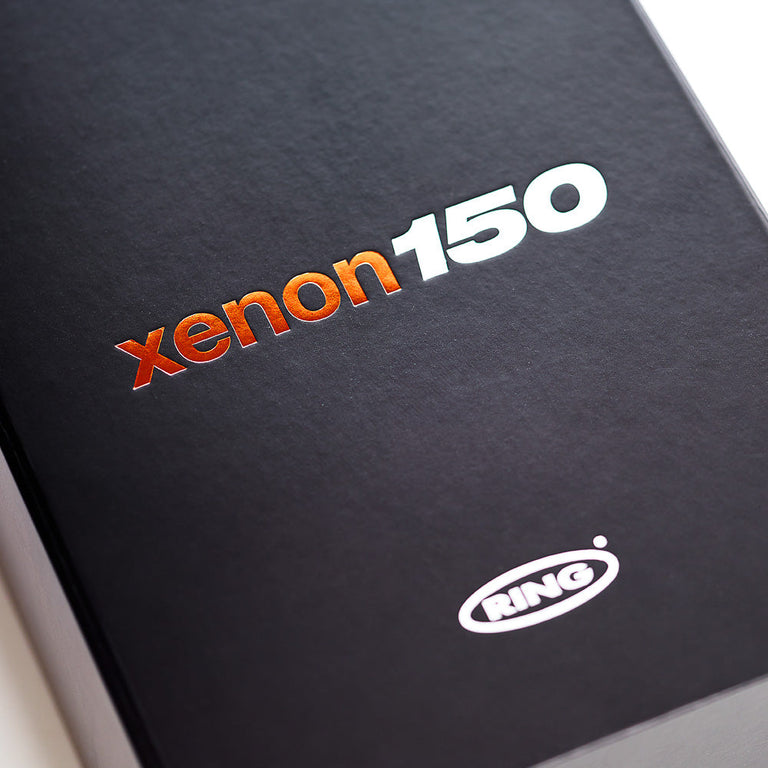

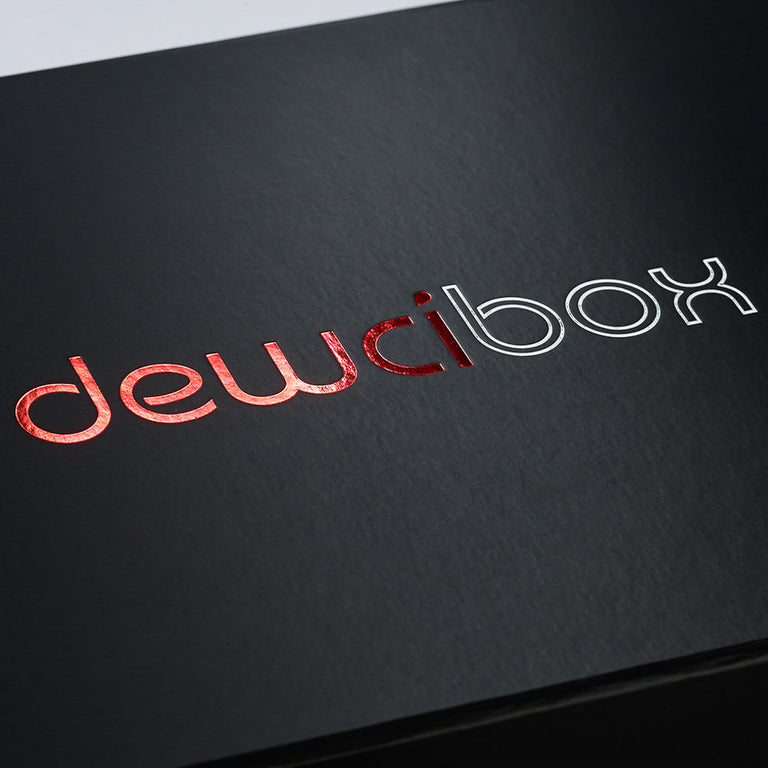

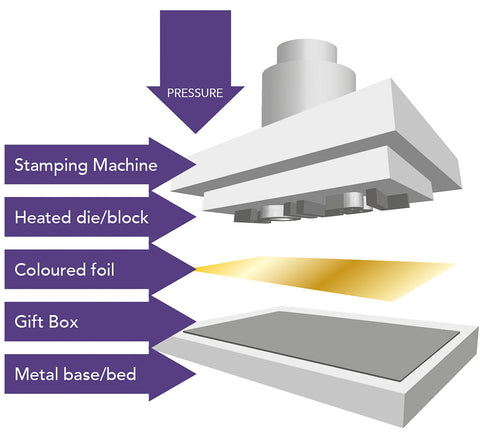

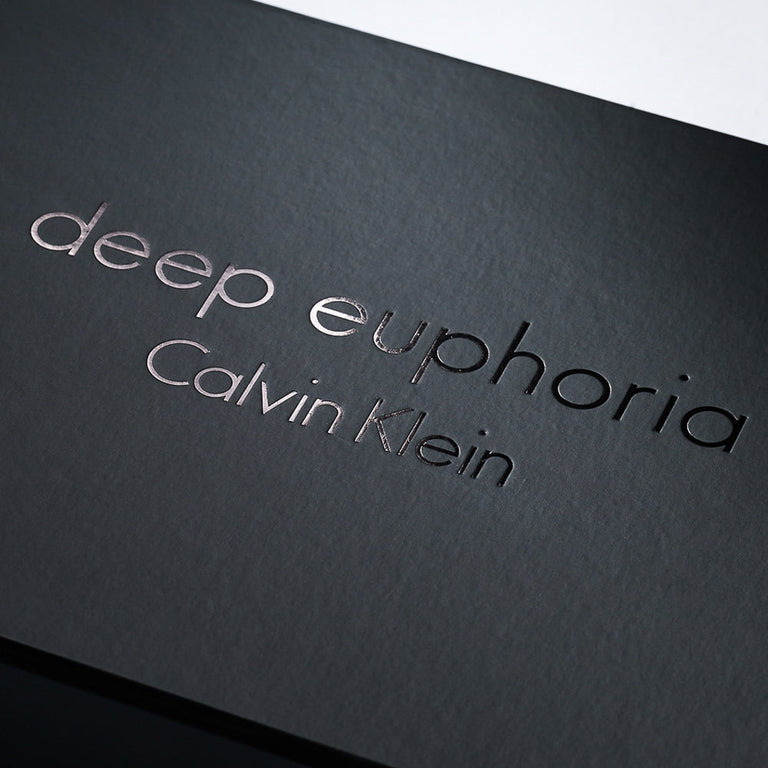

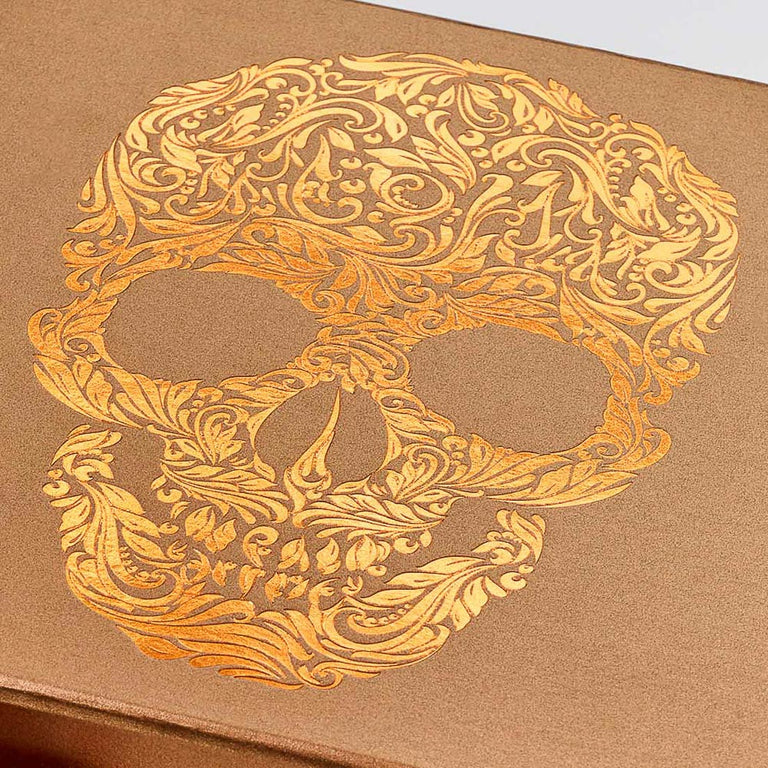

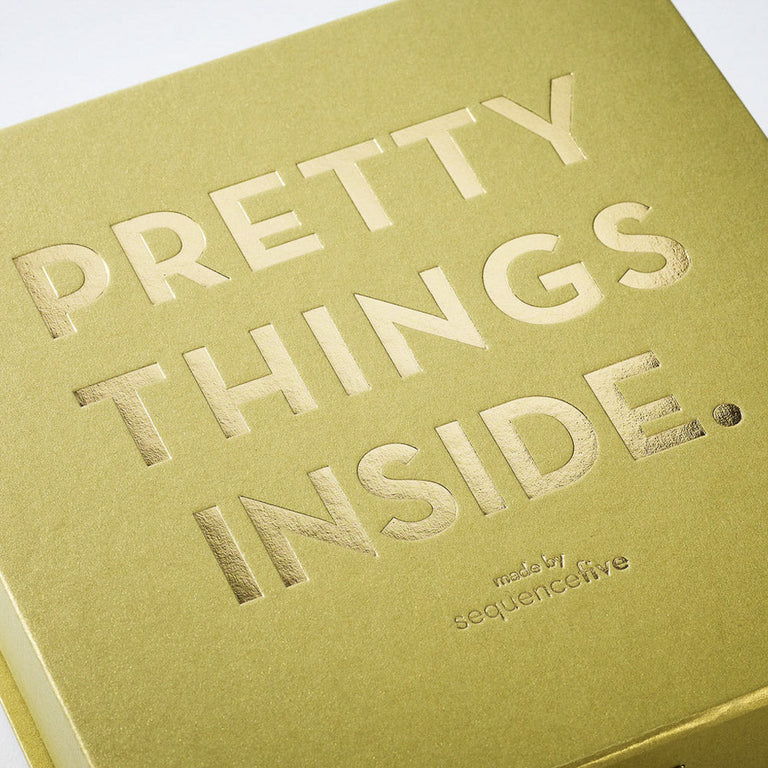

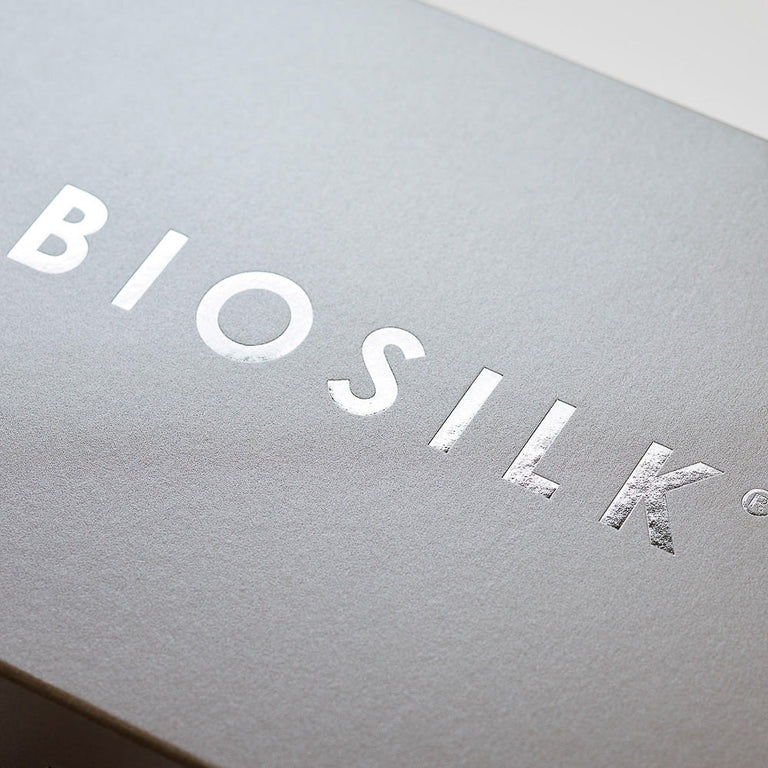

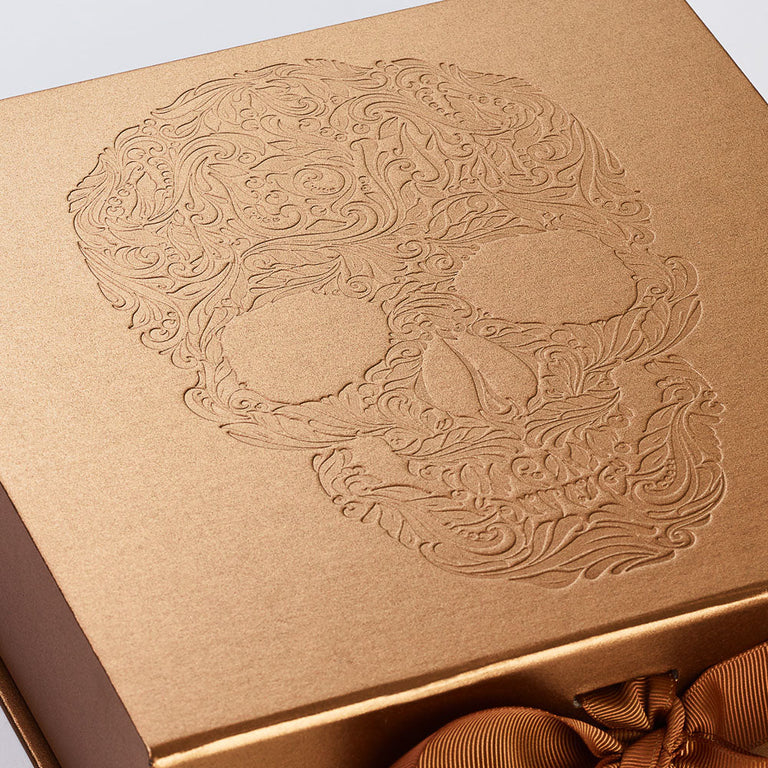

We can use foil, print ink to match a Pantone color, or deboss your logo. Multiple print colors and CMYK print are also possible depending on registration, design complexity and box color.

We cannot bleed print over the edges of the box and require a minimum 1cm border from the edge of the print logo or design to the edge of the box.

Allow around 2 weeks delivery for custom printing from receipt of your artwork and payment to delivery of printed boxes. Sooner delivery may be possible but during busy times, especially September - December it can take longer.

Due to the high volume of print enquiries, please allow 3 days for a custom print quotation.

Please submit the completed Jotform to enable Nigel Taylor our Print Manager to best assist you with a quotation.

If you are interested in 1,000 or more boxes in one of our standard sizes but with your custom color paper and print, or one of our stock colors to your own size, please submit your enquiry on our Bespoke Page. You will need to allow around 10-12 weeks for this option.

We also offer fully made to order boxes with many custom options shown in detail on our Bespoke Page on min. 2,000 boxes. You will need to allow 12-14 weeks for this option.

Send your printing enquiry

Please complete the below form to receive a quotation. We aim to respond as soon as possible, but due to high demand please allow 3 days.

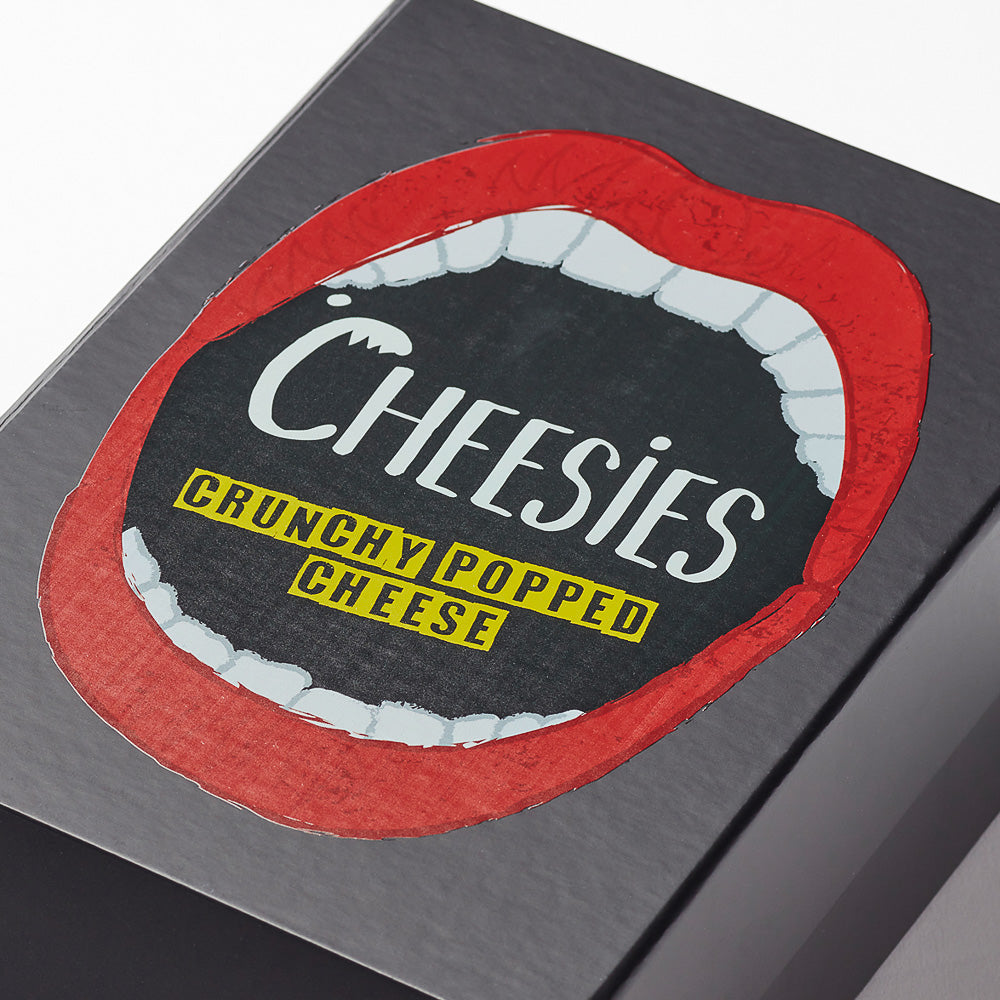

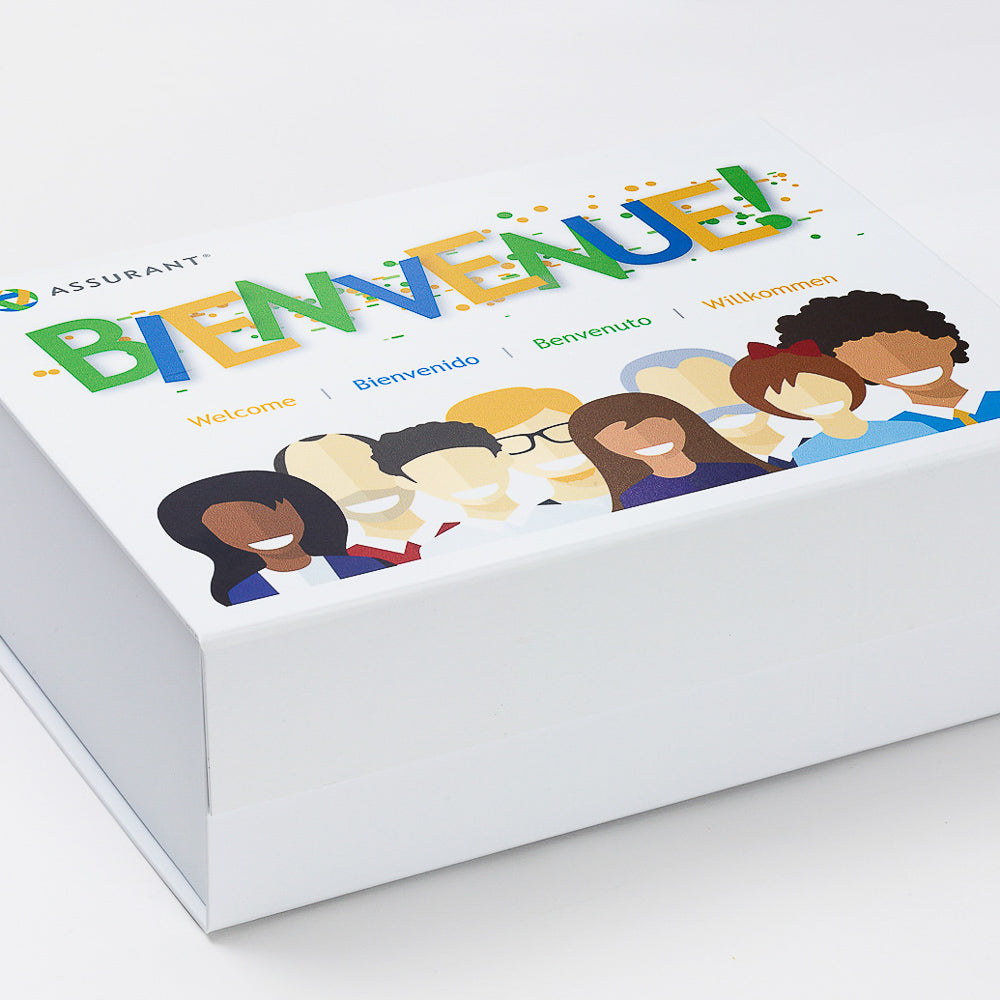

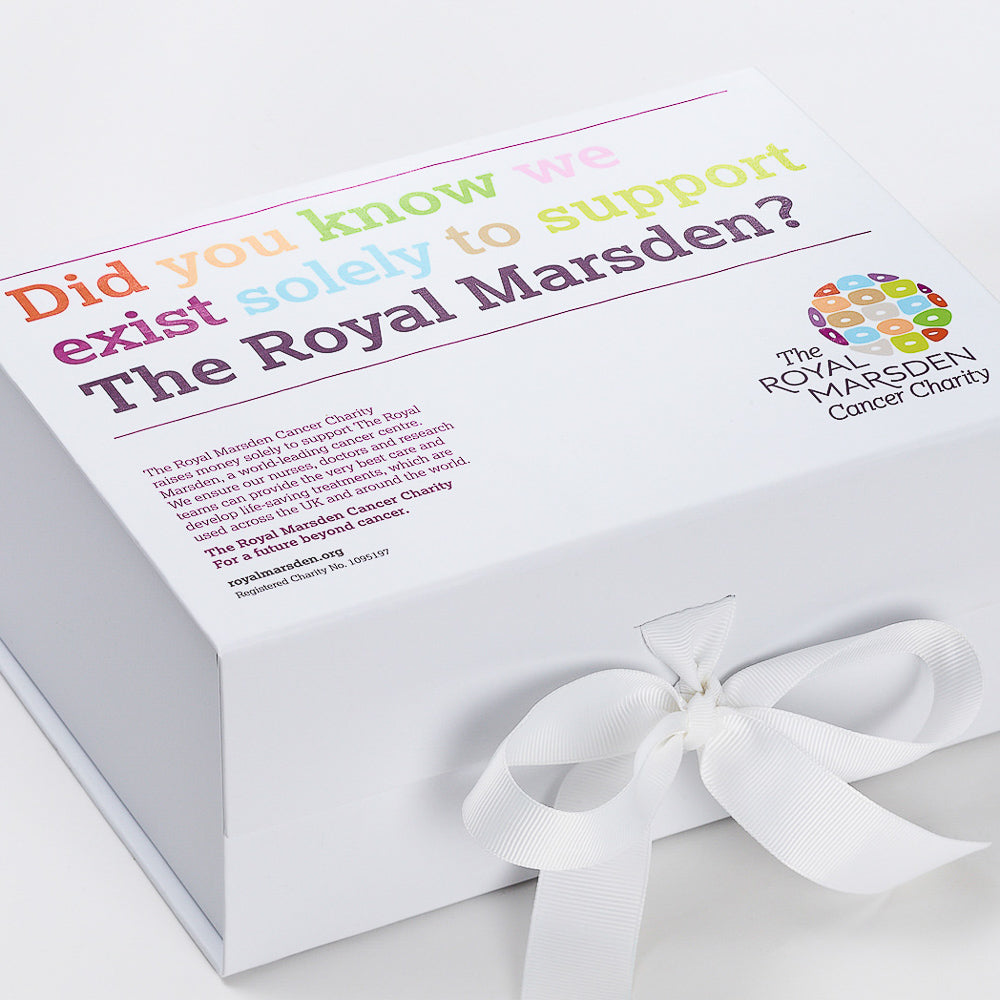

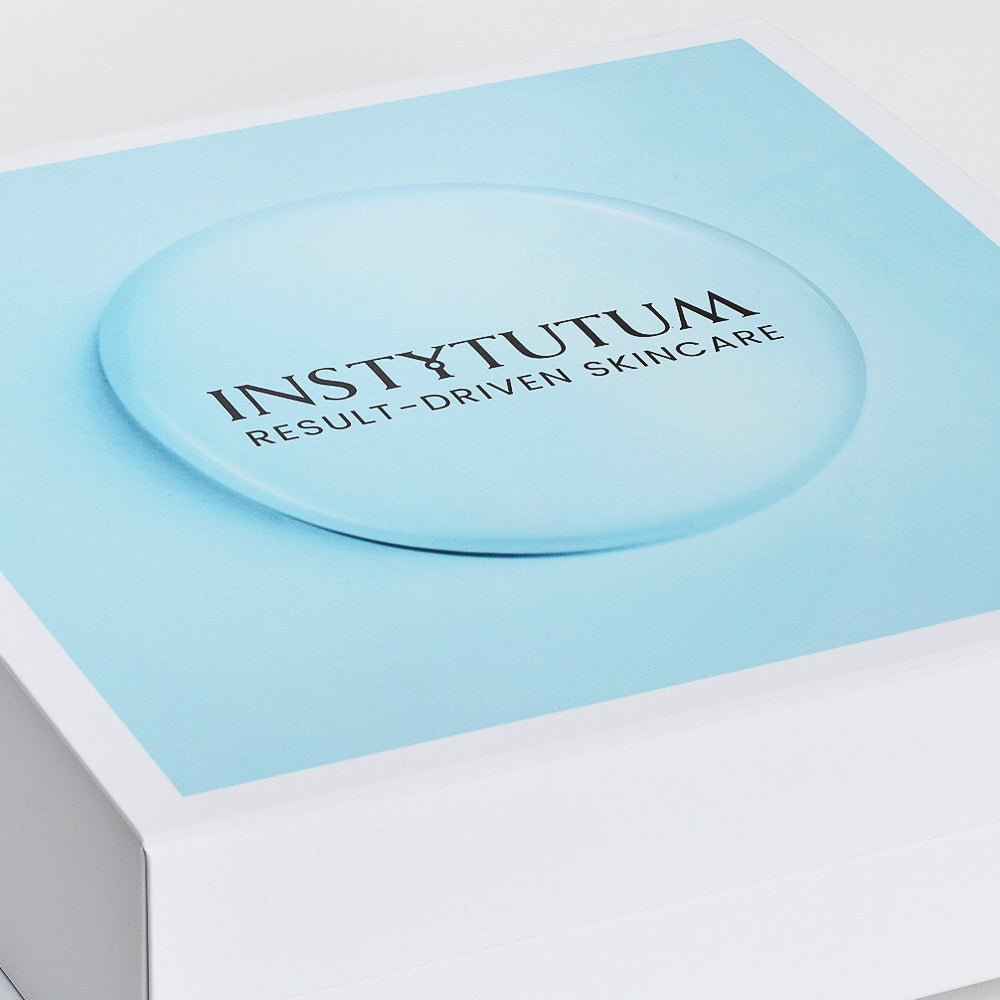

Printing Sample Gallery